Page 107 - Bord Bia

P. 107

ROADMAP

STAGE 1

f) Business Model

Continued

(i) BUILD - Distilling Equipment & Process

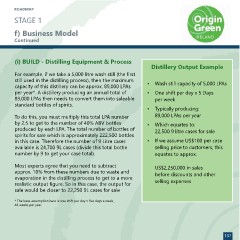

Distillery Output Example

For example, if we take a 5,000 litre wash still (the irst

still used in the distilling process), then the maximum

capacity of this distillery can be approx. 89,000 LPAs • Wash still capacity of 5,000 LPAs

per year*. A distillery producing an annual total of • One shift per day x 5 Days

89,000 LPAs then needs to convert them into saleable per week

standard bottles of spirits.

• Typically producing:

To do this, you must multiply this total LPA number 89,000 LPAs per year

by 2.5 to get to the number of 40% ABV bottles • Which equates to:

produced by each LPA. The total number of bottles of 22,500 9 litre cases for sale

spirits for sale which is approximately 222,500 bottles

in this case. Therefore the number of 9 Litre cases • If we assume US$100 per case

available is 24,700 9L cases (divide this total bottle selling price to customers, this

number by 9 to get your case total). equates to approx.

Most experts agree that you need to subtract US$2,250,000 in sales

approx. 10% from these numbers due to waste and before discounts and other

evaporation in the distilling process to get to a more

realistic output igure. So in this case, the output for selling expenses

sale would be closer to 22,250 9L cases for sale

* The base assumption here is one shift per day x ive days a week,

48 weeks per year.

107